These sensors attach to your equipment and serve as an early warning system, alerting you to potential issues before they escalate into costly repairs.

Our focus is on streamlining predictive maintenance, prioritizing both functionality and ease of integration.

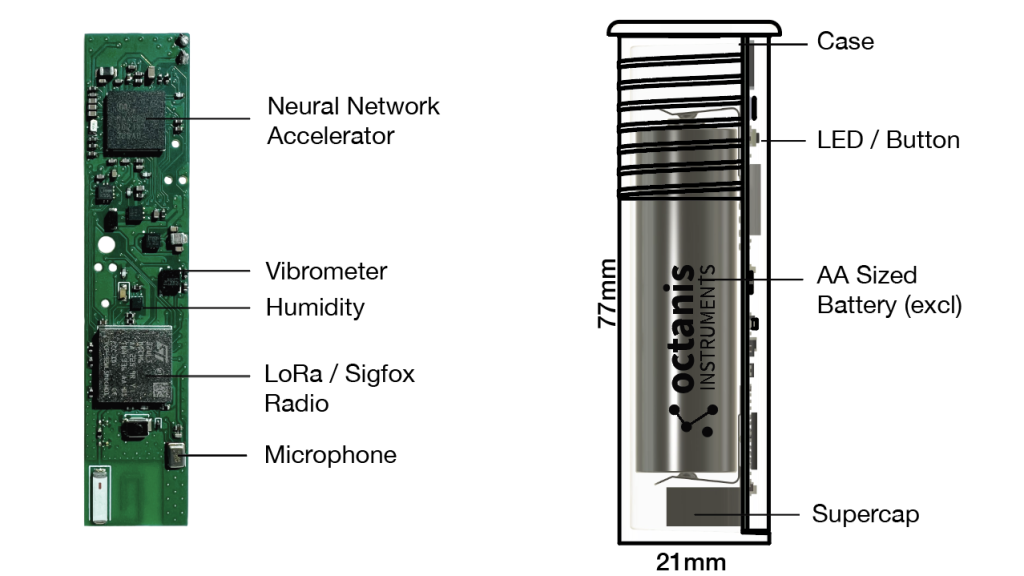

Meet ConvolutionSense: a wireless sensor node for both predictive maintenance and condition monitoring. It captures detailed vibration and sound data, converting it into clear, actionable results. Equipped with a potent 64-core neural network processor, it conducts complex analyses on the spot, sending alerts via LoRaWAN or Sigfox.

Data Analysis at the Edge is a core feature. The sensor’s 20kHz microphone and 6kHz tri-axis vibrometer detect irregularities directly on the device, bypassing the need for cloud processing. It's designed to handle specific, prolonged signal types that are difficult to classify remotely.

Interested in seeing how ConvolutionSense could fit into your operations? We’re ready to discuss your needs and potentially develop a customized sample for you to test. Let’s make predictive maintenance more intuitive and seamless together.